How many times have you seen a gap on a supermarket shelf, and on enquiring been told some variant of “Oh, it should have been on last night’s delivery, but wasn’t”? I know I’ve had this any number of times. Yet another failure of Just-in-Time delivery.

While this may be excusable when the product is perishable, like fresh fruit and veg, it really isn’t good enough for sanitary towels, drugs for the hospital, or parts for the factory down the road.

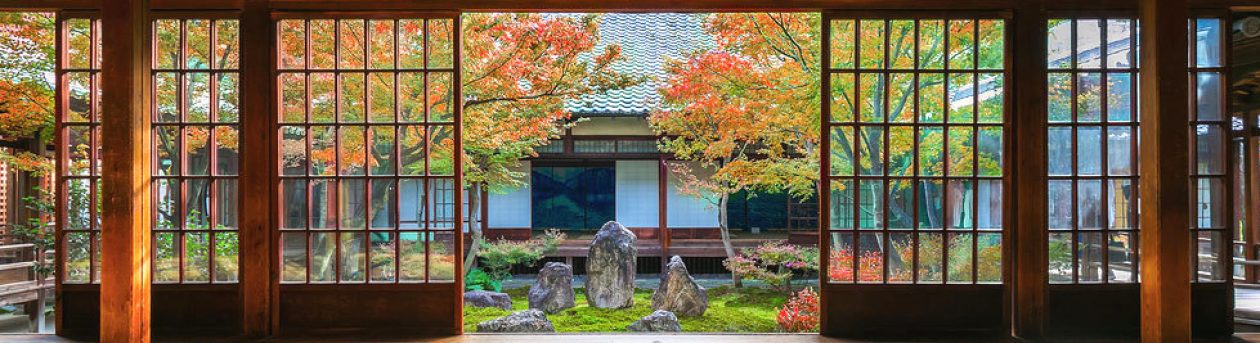

Just-in-Time delivery was a product of Toyota in 1950s Japan, and has taken over worldwide supply chain logistics since it hit the west in the 1980s.

Effectively every sector has seen it as a way of reducing cost: no idle stock overheads; no warehouses to be paid for; no warehouse staff to employ. And who can blame them when shareholders want ever more profit and managers need ever fewer overheads.

But as Kim Moody outlines in this Guardian article, there’s a problem. All too often it is Just-not-in-Time. Because the supply chain is now so incredibly complex and lengthy that any slight hiccup has a dramatic domino effect. And there is no safety margin in the way of warehoused stock.

A relatively small (in the overall scheme of things) hiccup can be enough to tip the balance. An unexpected exponential rise in natural gas prices. A large ship wedged sideways in the Suez Canal. A volcano erupting and disrupting aviation flight paths. And that’s without mega-disruptions like a pandemic, or own goals like Brexit.

Without every cog of the global supply chain working like well oiled clockwork, Just-in-Time isn’t. In today’s world logistics managers, and their downstream clients, work on the basis that the supply chain is working properly. They have no choice when the whole system is geared this way and they have no access to resources to provide contingency.

But, again as Moody points out, the contingency comes at a price – a price which is passed on to the end consumer. And as consumers we have gotten too used to ever cheaper everything, and fail to understand when prices rise. Joe Public doesn’t understand (or care about) economics; he cares about only his wallet and having strawberries all year round. Nor does he understand how this drive for ever faster capitalism is driving climate change.

We need to slow down. And we need to adjust the supply chains as well as our consumerism. We need to stop shipping stuff halfway round the world when we have the same product at home or very close by. Think: New Zealand lamb; Chilean wine; Peruvian asparagus – the examples are endless just in the supermarket. [On which note, well done to Waitrose for committing that all their own brand meat is British and for continuing to win awards for animal welfare.]

I end with Moody’s parting comment:

Now is the time to think about not just how we make and consume things, but also how we move them.